While many hope for the new year to deliver better income and opportunities, owner-operators content with no small number of challenges at mid-Winter. This time of year, weather and road conditions generally become a principal focus -- that is, until something worse interrupts daily planning.

How big a problem seems depends on many factors. Throughout last year, problems like parts sourcing and service delays, which would normally rank as smaller problems for many owners, have been multiplying, like snowfall building layer upon layer until an avalanche is inevitable.

Beginning last Fall, discussions surrounding the supply chain disruptions for truck parts and preventive maintenance service supplies, such as oil and those filters, began to build steam after signs early in the year that it could get worse. Some people heard the warnings and began stocking up with inventory for these normally readily available supplies.

[Related: Parts delays appear to be the rule for major service/repairs in 2021]

Yet at the end of the first week of the new year, I received a message from an owner indicating he was sitting at one of the nation’s largest truck stops and there was no oil for his routine service. Granted, he was looking for a synthetic 5W40, and other, more conventional oil types were available. But a quick canvass of the region around where he sat yielded much the same – nothing available. I have been doing some Internet searching as of late, and some companies indicate it may be 30 plus days until they receive products that are short, whether oil or something else.

Given these dynamics, new truck manufacturing interruptions, more miles on current equipment and so much more, there’s a definite repair and maintenance backlog for lots of owners. The high cost of downtime can easily overwhelm an owner-operator’s ability to meet business and personal needs.

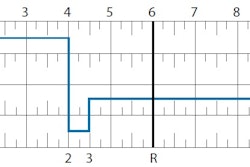

Owner-operator David Nihart of Wilmington, Ohio, uses the OPS bypass filter system with his 2007 Cummins ISX CM-870. The truck has 870,000 miles on the odometer. He currently samples and test engine oil every 25,000 miles. He historically changes every 50,000 miles, based on soot levels.